COUNTER ASSIGNMENT

Counter assignment refers to the process of linking an input field or formula to an individual part number counter within the Fields and Formulas sub-module. This assignment determines the source of accumulation for the counter, specifying how the hours or landings value of a linked part (or part assembly) is calculated and updated.

For instance, in the case of the RIN counter of a Bell 205 main rotor mast part number, a formula called "B205 Main Rotor Mast RIN" would be assigned to it. This formula acts as the source of accumulation for the RIN counter, and the counter value is updated based on the calculated output of the formula and applied as hours or landing accumulation to the part assembly. The formula determines the rate at which the RIN counter accumulates, incorporating relevant variables, input fields, and mathematical operations.

Similarly, the Starts counter of an engine part number can be assigned an input field called "Starts." Each Flight Log's Starts quantity input is used as the source of accumulation for the Starts counter. The counter value is updated based on the Starts quantity provided in each Flight Log, enabling the tracking of engine start events.

By assigning input fields or formulas to specific counters, users can establish the mechanisms by which the counters accumulate data. This flexibility allows for dynamic and automated accumulation based on calculated outputs or user-provided inputs, enhancing the accuracy and efficiency of data tracking.

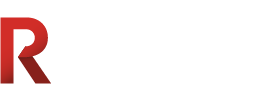

Assignment of a Counter to a New Part Number

When a Part Number has not yet had a counter defined for a particular Applicable Installation, the following workflow allows the user to initialize this Part Number’s counters for the associated Applicable Installation.

Select Input Fields & Formulas from the Technical Records module.

Select an Applicable Installation listed in the left-hand listing to expand an Applicable Installation.

Select Assign Counter below the expanded Applicable Installation to open the Counter Assignment sub-module.

Select a Search Type, enter the Search Criteria, and click the Find button. Select the desired Part Number from the drop-down list.

With the Part Number selected, define the Hrs Assignment and Cyc Assignment for the Part Number when installed into the specified position. The help document Fields, Formulas & Variable Input Definition provides an overview of how to define both Fields and Formulas for usage when defining the Hrs Assignment and Cyc Assignment formulas.

Note: A blank position may be entered. A blank position will be used when the specified Part Number accumulates time and does not have an explicit positional counter defined. For example, a landing gear with a counter defined for blank, LH MLG and RH MLG positions will use the blank counter when the specified Part Number accumulates time when installed to a position that is not LH MLG or RH MLG. As such, the position of installation is an important factor to consider when assigning counters to an Applicable Installation.

Select the checkmark icon to save the new Counter.

Figure 1: Assignment of a Counter to a New Part Number

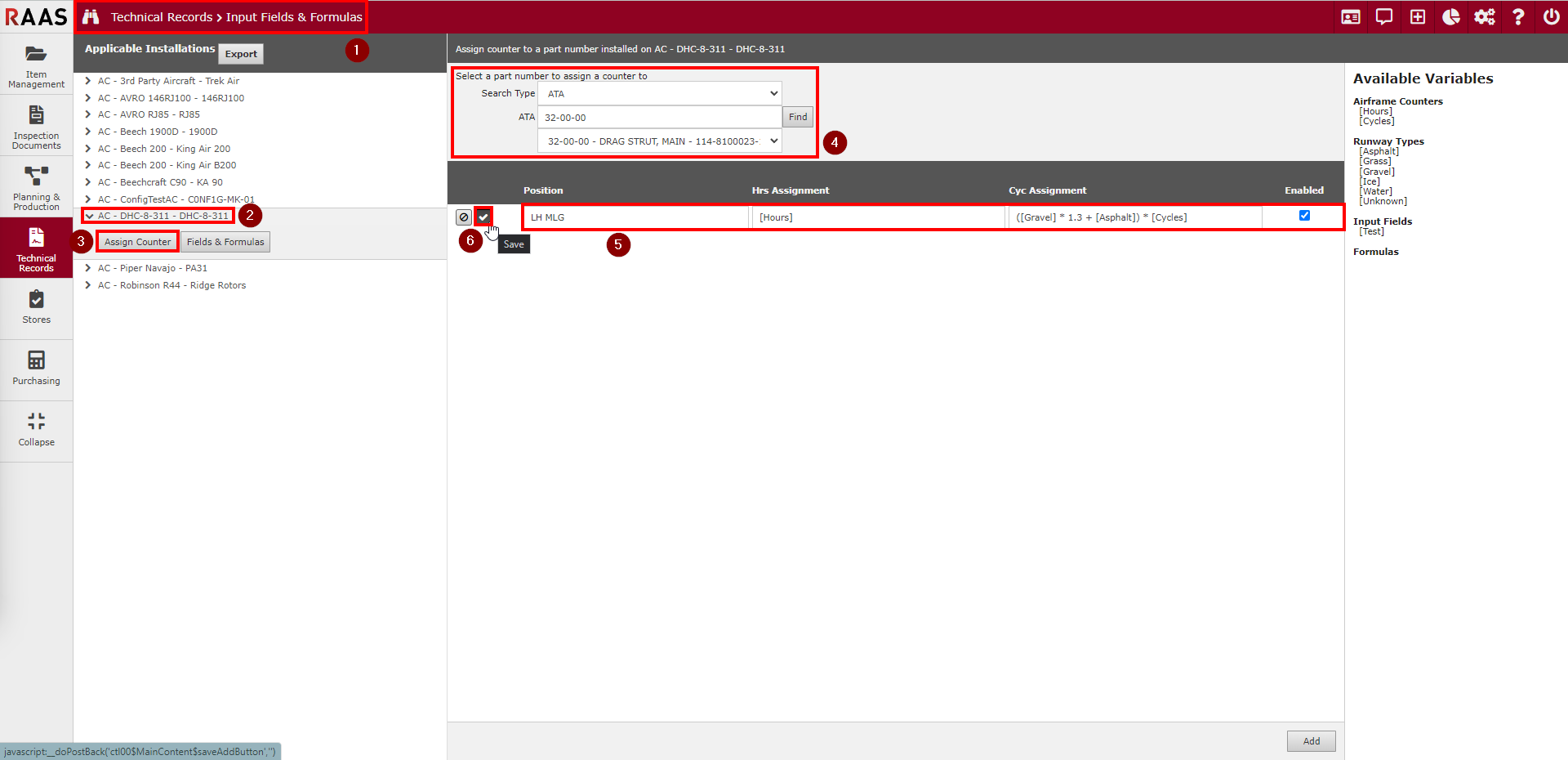

Modification of Existing Part Number Counters

When a Part Number already has one (or more) counters associated to a particular Applicable Installation the following workflow allows the user to modify existing counters and add new positional counters as required.

Select Input Fields & Formulas from the Technical Records module.

Select an Applicable Installation listed in the left-hand listing to expand an Applicable Installation.

Select the edit icon beside a listed Part Number to view counters associated to that Part Number.

Select either the Add button in the bottom right of the module, or the edit icon beside a listed counter to allow for modifications to a new or existing counter.

Define the Hrs Assignment and Cyc Assignment for the Part Number when installed into the specified position. The help document Fields, Formulas & Variable Input Definition provides an overview of how to define both Fields and Formulas for usage when defining the Hrs Assignment and Cyc Assignment formulas.

Note: A blank position may be entered. A blank position will be used when the specified Part Number accumulates time and does not have an explicit positional counter defined. For example, a landing gear with a counter defined for blank, LH MLG and RH MLG positions will use the blank counter when the specified Part Number accumulates time when installed to a position that is not LH MLG or RH MLG. As such, the position of installation is an important factor to consider when assigning counters to an Applicable Installation.

Select the checkmark icon to save the Counter.

Figure 2: Modification of Existing Part Number Counters