REPAIR ORDERS

Items being sent out for repair should be placed on a separate Order, known as a Repair Order.

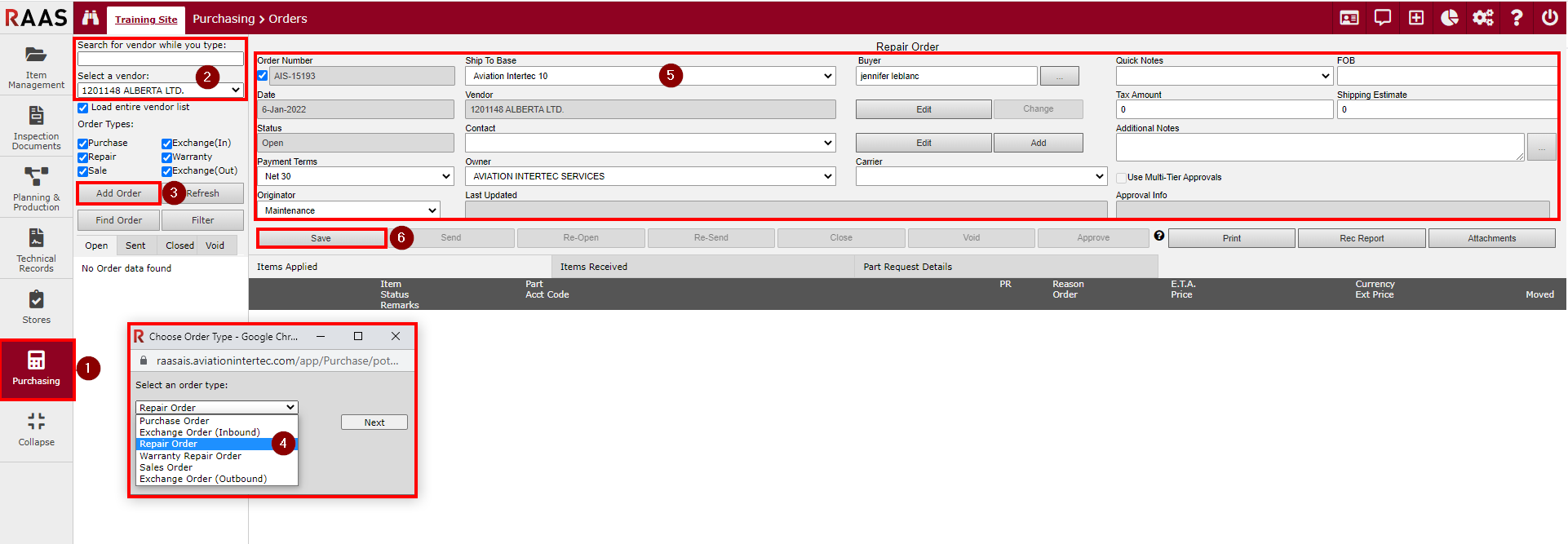

Creating a Repair Order (RO)

Click on Purchasing and select Orders.

Select the Vendor to which the item(s) will be sent for repair and click Refresh.

Click the Add Order button.

Select Repair Order from the Order Type dropdown and click Next.

Enter the shipping and vendor information, such as Ship To Base, Buyer, Vendor Contact, Payment Terms and Carrier.

Note: RAAS will automatically assign an Order Number if auto-numbering is selected in Company Settings. If desired, the Order Number can be manually entered by deselecting the Order Number checkbox and entering a number. Once the header is saved the order number can no longer be changed.Click Save.

Figure 1: Creating a Repair Order

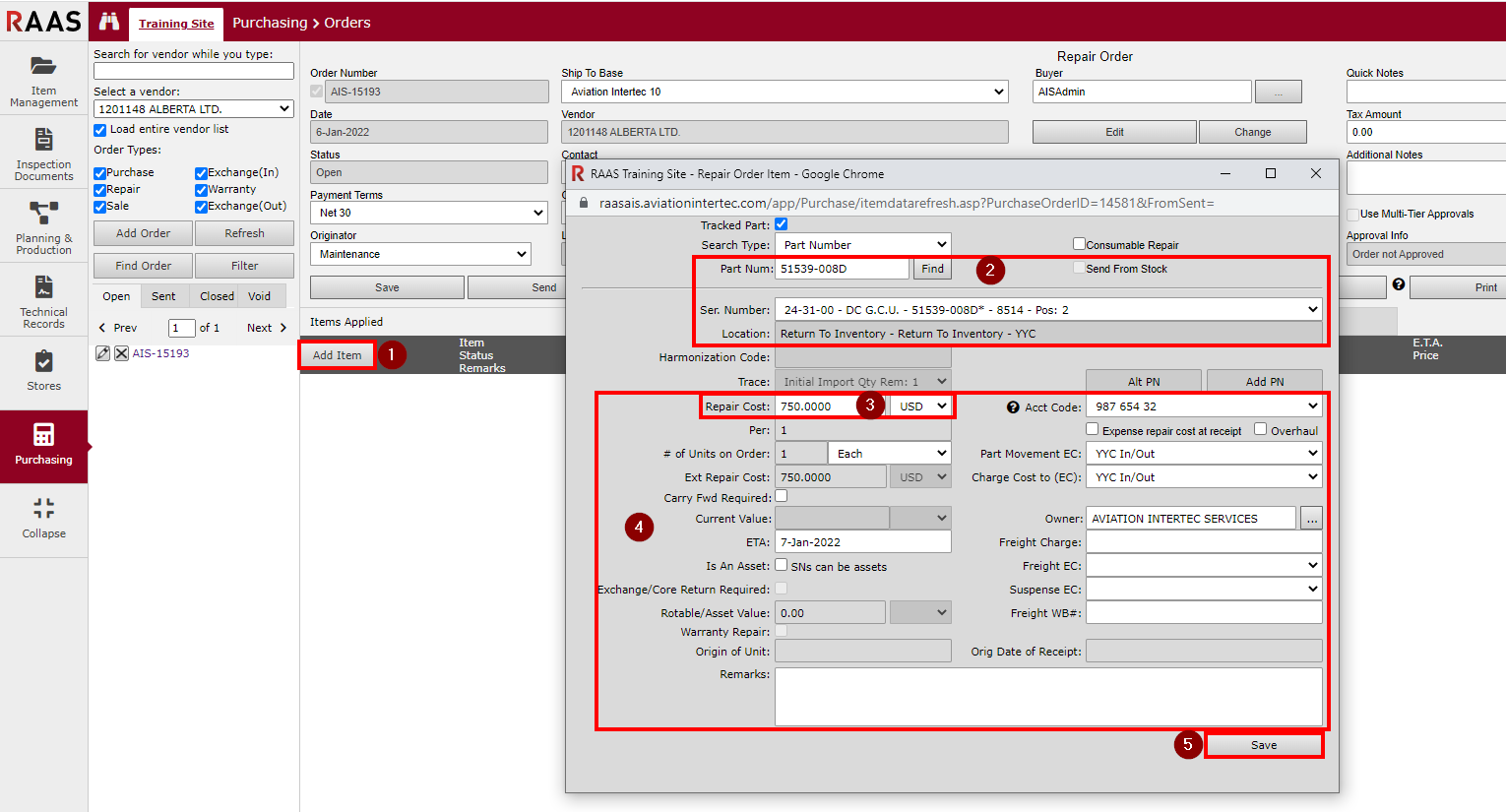

Adding Non-Consumable Items to a Repair Order

On the Items Applied tab, click the Add Item button to open the Repair Order Item screen. Notice that this screen is different than the Purchase Order Item screen as this screen requires the selection of the specific Serial Number in need of repair, as well as the part’s current location.

If the item to be sent for repair is a Non-Consumable, search for the Part and select the correct Serial Number. Note that a part can be added to a Repair Order while it is still installed on an aircraft, but before it can be sent, the part must be removed from the aircraft. Parts are most commonly in “Return To Inventory” when sent for repair.

If known, enter the expected Repair Cost. Note that this can be entered/adjusted later if necessary.

Enter any remaining details of the repair order.

Click the Save button.

Figure 2: Adding Non-Consumable Items to a Repair Order

Notes:

The option to select an Account Code will only be available if the “Account code required at item receipt” option is selected in the Purchasing / Shipping / Receiving Information section on the Company Settings page in Options.

The Expense repair cost at receipt option will be on or off based on the Company Setting under Accounting Preferences. Expense repair cost at receipt is used when the company wants to expense the repair cost to the aircraft the part was just removed from instead of expensing the repair cost when the part is issued.

Non-tracked items should always be expensed at receipt to Expense Centers created for specific non-tracked/misc. expenses.

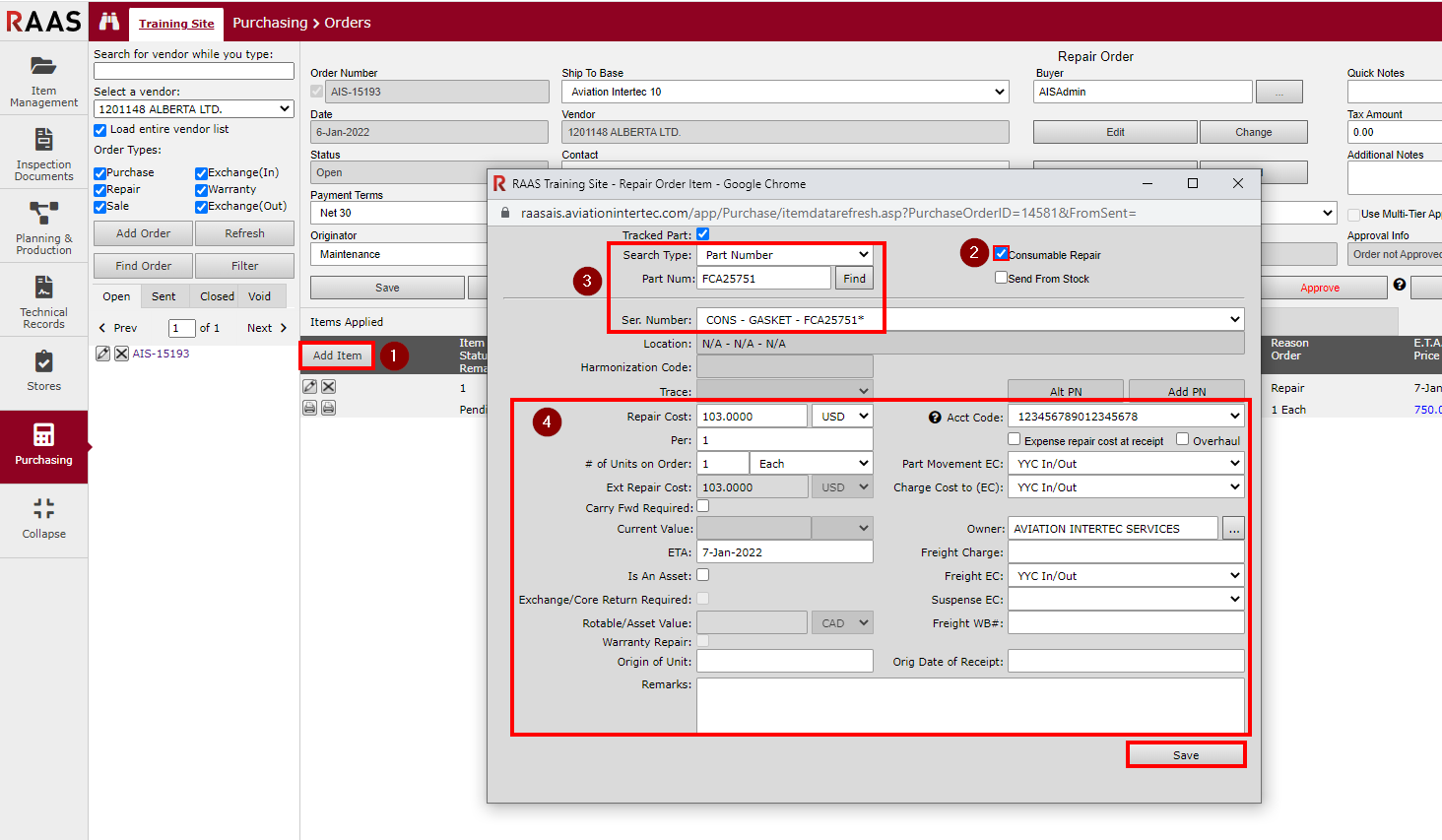

Adding Consumable Items to a Repair Order

On the Items Applied tab, click the Add Item button to open the Repair Order Item screen.

Select the Consumable Repair checkbox.

Note: Send from Stock would only be selected if the part is in inventory and has not been issued. This is not typical.Search for the Part by Part Number or Part Description. The Consumable Repair and Send from Stock selections must be made before clicking Find. Select the correct consumable Ser. Number.

Enter the expected Repair Cost and # of Units on Order. Note that the repair cost can be adjusted later if necessary. Also, enter any other remaining details of the order.

Click the Save button.

Figure 3: Adding Consumable Items to a Repair Order

Notes:

The option to select an Account Code will only be available if the “Account code required at item receipt” option is selected in the Purchasing / Shipping / Receiving Information section on the Company Settings page in Options.

Expense repair cost at receipt is used when the company wants to expense the repair cost to the aircraft the part was just removed from rather than expensing it at issue.

Non-tracked items should always be expensed at receipt to Expense Centers created for specific non-tracked/misc. expenses.

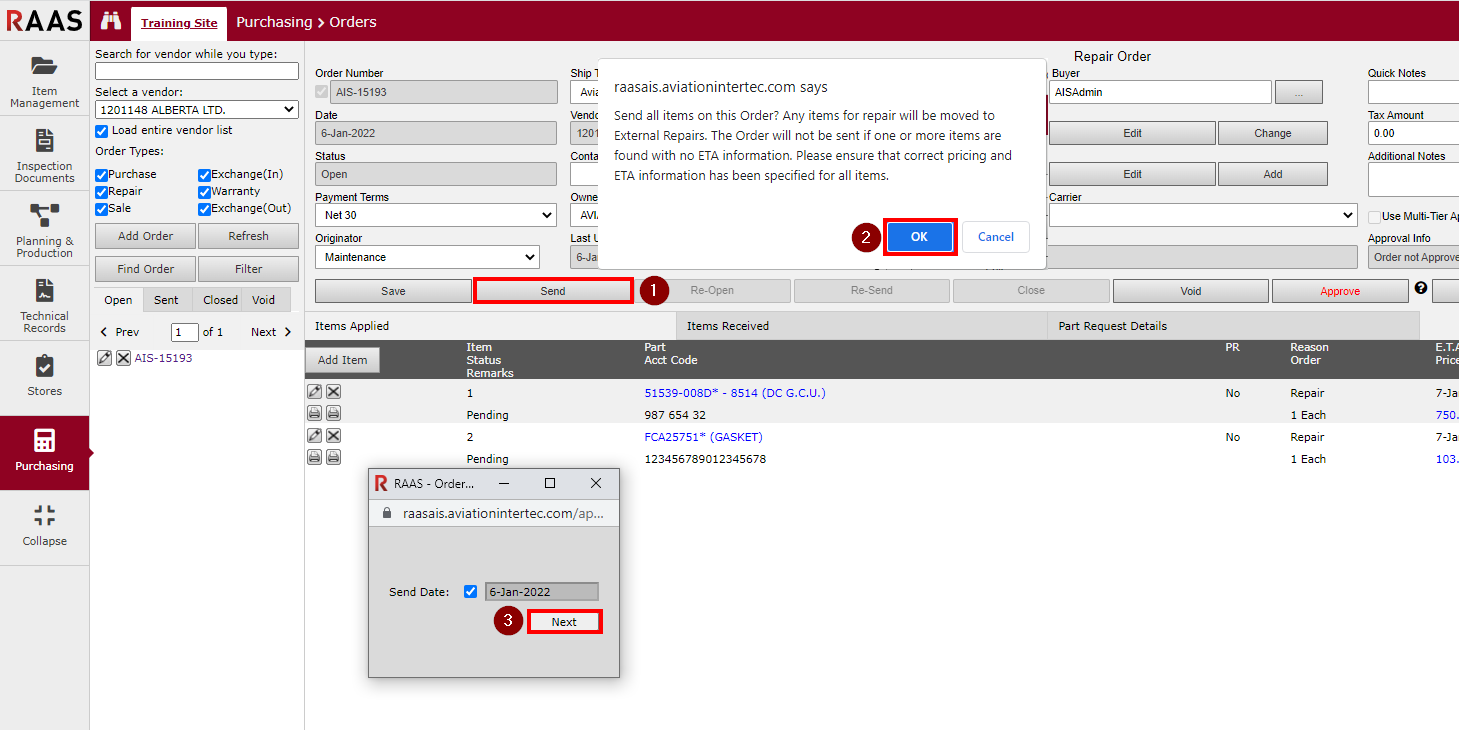

Sending a Repair Order

Once all required items have been added to the Repair Order, take a moment to verify that the pricing is correct and that ETA information has been specified for all items.

Click the Send button.

Click OK to continue.

Enter a Send Date or click the checkbox to enter the current date and click Next.

Figure 4: Sending a Repair Order

When the Repair Order is sent, the screen refreshes and the RO Status is changed from Open to Sent. The Order Number Listing will also be refreshed and the RO number will appear under the Sent tab. Any non-consumable parts will be moved to External Repairs. The status of each item on the Repair Order will be changed to Shipped.

If an item cannot be moved to External Repairs from its current location a message will come up saying that the order cannot be sent.

Receiving RO Items

Once an item on a Repair Order (RO) has been received back from a vendor, the transaction must be recorded in RAAS. The Items Received tab, within the Orders sub-module, allows the receiver to track the receipt of items that have been repaired.

To receive an item on an order, the order must have been sent and the status of the item you are receiving must not be closed on the Items Applied tab of the order.

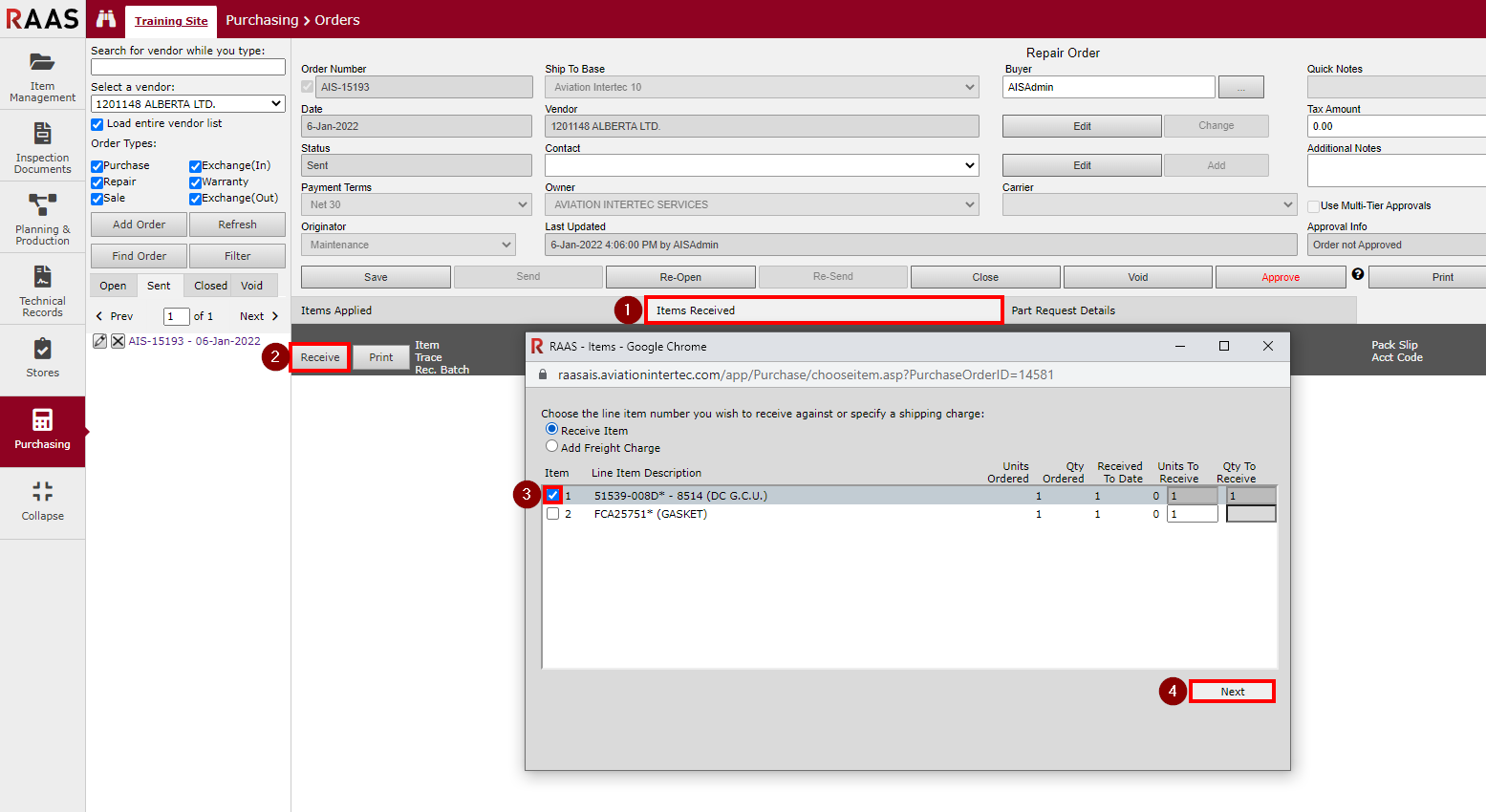

Receiving Non-Consumable Repaired Items - Wizard Page 1

Locate the Repair Order on which the item to be received was entered and click on the Items Received tab.

Click the Receive button to begin receiving the items listed on the RO.

Select the item being received.

Click Next.

Figure 5: Receiving Non-Consumable Repaired Items

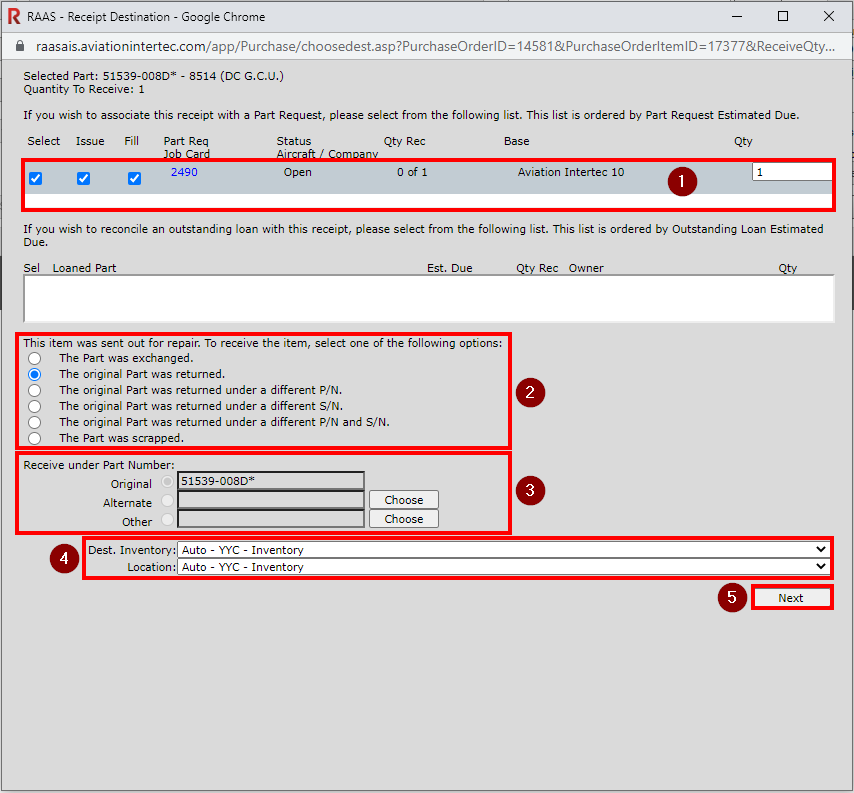

Receipt Destination for Non-Consumable Repaired Items - Wizard Page 2

If the item being received is being claimed by a part request, the part can be issued and the part request filled/closed during receipt.

Select the applicable repair option:

The Part was exchanged - This option moves the SN sent to Dead and the user must enter the SN received in exchange in the next window.

The original Part was returned - Part Number options disabled

The original Part was returned under a different P/N - allows user to select a different Part Number – the SN is moved to the PN selected just as it would be if the SN Change PN function were used.

The original Part was returned under a different S/N - Part Number options disabled – the new SN is entered in the next window.

The original Part was returned under a different P/N and S/N - allows user to select a different Part Number and the new SN is entered in the next window.

The Part was scrapped - Destination Inventory and Location will be set to Dead – the SN sent will be moved to Dead. The user still must fill in the details in the next window.

Select the applicable Receive under Part Number option based on repair option selection. If selecting Alternate or Other, click the Choose button beside the selection to choose a different part number.

Alternate - choose an alternate part number located under the same part description

Other - choose a part number under a different part description

Verify that the item is being received to the correct Destination Inventory and Location. All five Inventory sub-locations appear in the Location drop-down, however, only the Awaiting Repair and Quarantine locations would be selected based on the status of the part being received. Tool Crib would be the default if the Item Type of the item being received is Tool.

Click Next.

Figure 6: Receipt Destination for Non-Consumable Repaired Items

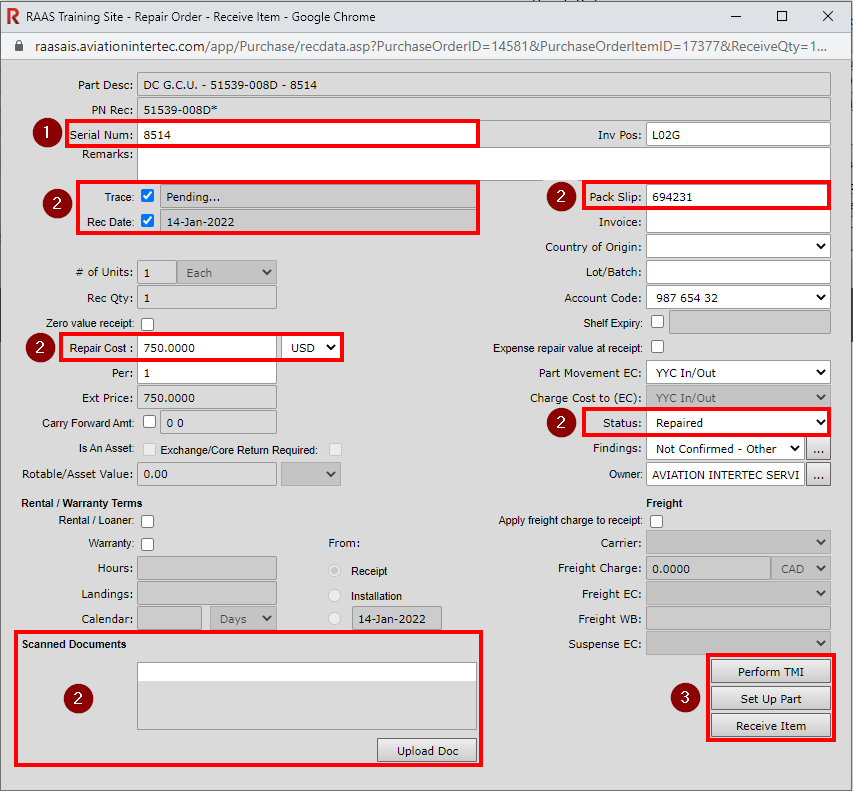

Repair Order - Receive Item for Non-Consumable Repaired Items - Wizard Page 3

The behaviour of the Serial Num field will vary depending on the selections on the previous page. If the selection chosen includes that the Part was returned under a different S/N, a new Serial Number will need to be entered. If the original Part was returned with the same Serial Number, the Serial Num field will be populated with the original Serial Number and cannot be changed.

Enter the remaining receipt data provided on the packing slip. The mandatory fields for Non-Consumable parts include Serial Number, Trace, Pack Slip, Rec Date, Repair Cost, Status and Scanned Documents (if enabled in Company Settings). If the Repair Cost is zero, select the Zero value receipt checkbox and enter a Reason.

An important data item is the Trace number. The trace number is used to track a particular part item back to its supplier. Complete trace information for an item can be viewed from the serial number detail screen – see TRACE INFORMATION. RAAS will automatically assign a Trace number if Auto Trace Numbering is selected in Company Settings, or the checkbox can be removed to enter a Trace number manually. Another option in Company Settings is to “Use Order Number as default trace at item receipt.”

Entering Rental/Warranty Terms will drive expiration reports and trigger the Warranty Removal email notification.

Findings will show up on the Rate of Removal Report. The options in the Findings dropdown menu are added in Settings - Vendor Findings.

Once all details are entered on the Receive Item page, the user can choose to Perform TMI, Set Up Part, or Receive Item.

Perform TMI – this action will receive the item and then begin a new TMI Log Entry. See TMI MAINTENANCE ENTRY to complete the TMI Entry.

Set Up Part – this action will receive the item and then allow you to set up the item through inventory by opening the Serial Number screen.

Receive Item – this action will receive the item.

Items received will now appear on the Items Received tab of the Repair Order and the part will be put in Inventory. The item status will be changed to Closed on the Items Applied tab. If the final item of the order is being received, the user will be asked if they want to close the order.

Figure 7: Receive Item for Non-Consumable Repaired Items

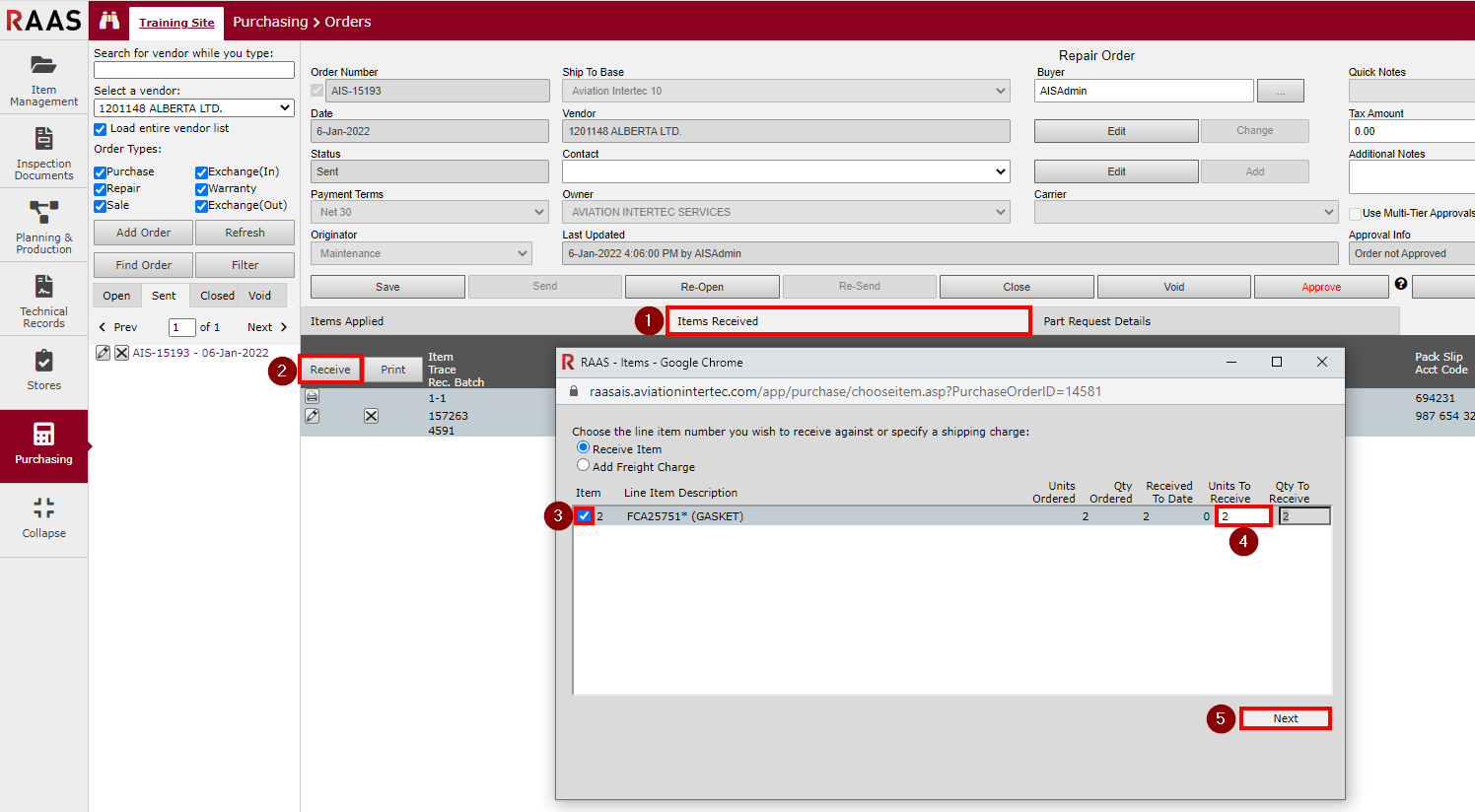

Receiving Consumable Repaired Items - Wizard Page 1

Locate the Repair Order on which the item to be received was entered and click on the Items Received tab.

Click the Receive button to begin receiving the items listed on the RO.

Select the consumable item being received.

Enter the number of Units to Receive.

Click Next.

Figure 8: Receiving Consumables Repaired Items

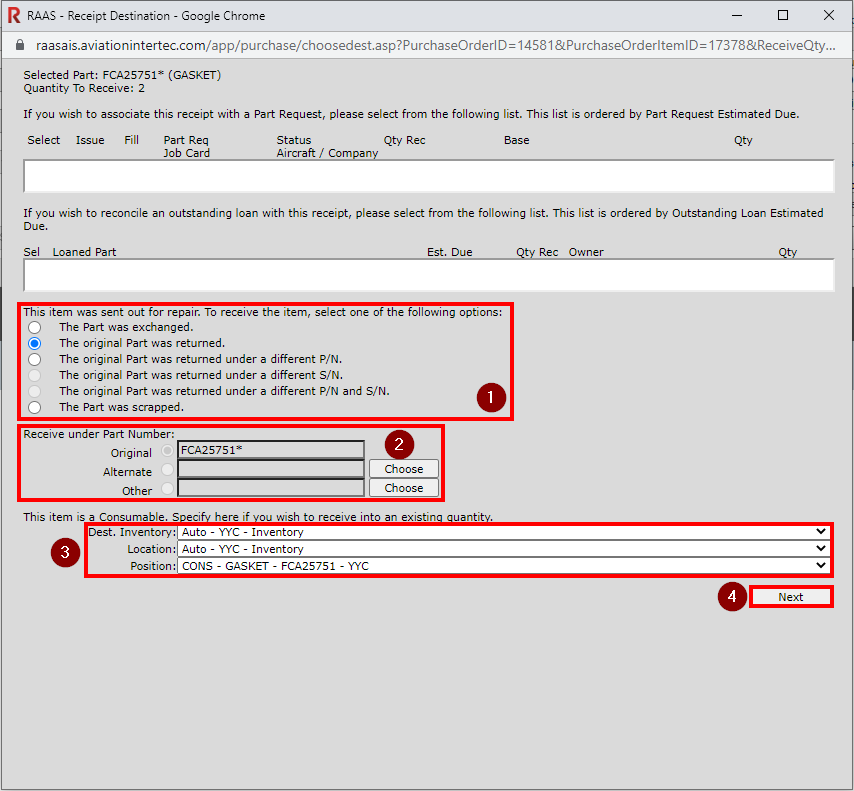

Receipt Destination for Consumable Repaired Items - Wizard Page 2

If the item being received was ordered in response to a part request, the part can be issued and the part request filled/closed during receipt. When a consumable item is being received, the quantity or a portion of the quantity can be issued and the part request filled/closed. Issuing a consumable item will expend/remove from stock the quantity issued.

Select the applicable repair option:

The Part was exchanged - allows user to select a different Part Number

The original Part was returned - Part Number options disabled

The original Part was returned under a different P/N - allows user to select a different Part Number

The original Part was returned under a different S/N - this option cannot be selected as it is only for non-consumable parts

The original Part was returned under a different P/N and S/N - this option cannot be selected as it is only for non-consumable parts

The Part was scrapped - Destination Inventory and Location will be set to Dead. A new consumable position in the inventory will be created if it does not already exist.

Select the applicable Receive under Part Number option based on repair option selection. If selecting Alternate or Other, click the Choose button beside the selection to choose a different part number.

Alternate - choose an alternate part number located under the same part description

Other - choose a part number under a different part description

Verify that the item is being received to the correct Destination Inventory, Location and Position (consumable bin).

Click Next.

Figure 9: Receipt Destination for Consumable Repaired Items

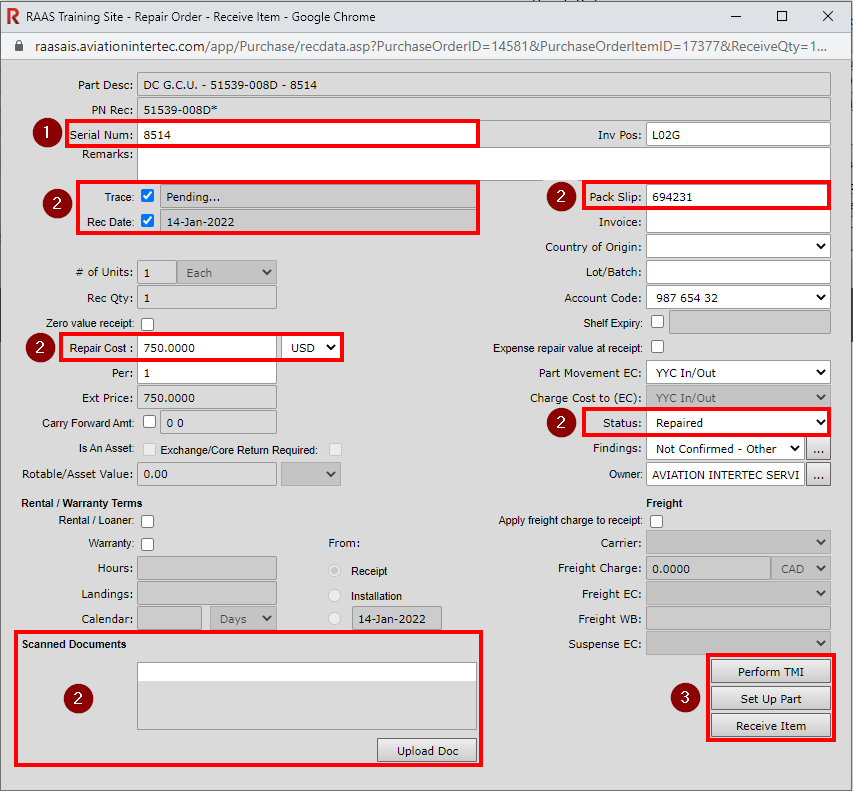

Repair Order - Receive Item for Consumable Repaired Items - Wizard Page 3

The behaviour of the Serial Num field will vary depending on the selections on the previous page. If an existing Position was selected, the Serial Number will be automatically populated with Serial Number of that position. If “Create new consumable position in this inventory” was selected for the Position, you will need to enter a Serial Number for the new consumable position. This is normally the base (ex. YYC, YQT, etc.).

Enter the remaining receipt data provided on the packing slip. The mandatory fields for Consumable parts include Serial Number, Trace, Pack Slip, Rec Date, Repair Cost, and Status. If the Repair Cost is zero, select the Zero value receipt checkbox and enter a Reason.

An important data item is the Trace number. The trace number is used to track a particular part item back to its supplier. This is particularly important for consumables. Complete trace information for an item can be viewed from the serial number detail screen – see TRACE INFORMATION. RAAS will automatically assign a Trace number if Auto Trace Numbering is selected in Company Settings, or the checkbox can be removed to enter a Trace number manually. Another option in Company Settings is to “Use Order Number as default trace at item receipt.”

Entering Rental/Warranty Terms will drive expiration reports and trigger the Warranty Removal email notification.

Once all details are entered on the Receive Item page, the user can choose to Perform TMI or Receive Item.

Perform TMI – this action will receive the item and then begin a new TMI Log Entry. See TMI MAINTENANCE ENTRY to complete the TMI Entry.

Receive Item – this action will receive the item.

Figure 7: Receive Item for Non-Consumable Repaired Items

Items received will now appear on the Items Received tab of the Repair Order and the part will be put in Inventory. The item status will be changed to Closed on the Items Applied tab. If the final item of the order is being received, the user will be asked if they want to close the order.