PICK LISTS AS A MATERIAL REQUEST DASHBOARD

Using the Pick List User Interface as a Material Requests Dashboard

The Pick List Listing has been designed to handle several different user workflow scenarios, including:

a) Mobile tablet-based stock taking

b) Dedicated Material Requests Dashboard shown on a large screen display to facilitate visual notification of inbound material requests.

To use the Pick List Listing as a Material Requests Dashboard, it is essential to understand how the Pick List Status and Pick List Assignee data elements influence user workflow, along with the Auto-Refresh feature of the Pick List Listing.

Pick List Status

Pick Lists can have a status of New, Open and Closed.

A Pick List with a status of New is one that is being put together, is still having Part Requests added to it, and is not ready to have the stock picked yet.

A Pick List with a status of Open is ready to have the stock picked.

A Pick List with a status of Closed is one where all the Part Requests in the Pick List have been satisfied or the Part Requests have been removed from the Pick List.

The Material Requests Dashboard filter would ideally be set to show only Pick Lists that have a Status of Open.

Pick List Assignee

Pick Lists can be Assigned to an individual RAAS user.

Newly created Pick Lists are assigned to no user; they are Unassigned.

The Material Requests Dashboard filter would ideally be set to show only Pick Lists that are Unassigned.

Auto-Refresh

When enabled, the Auto-Refresh setting at the top of the Pick List Listing automatically refreshes the Listing periodically. New Pick Lists created through external processes will appear in the Listing with an audible alert. As users address Pick Lists by assigning them, fulfilling them, or changing their status to Closed, they will be removed from the Listing.

The Materials Request Dashboard would ideally have the Auto-Refresh setting enabled.

When the Material Requests Dashboard filters and auto-refresh are configured as described above, it will visually notify users of new inbound Pick Lists that require immediate stock picking.

Stores Personnel Actions

When new Pick Lists arrive, Stores personnel can take several actions:

Print a Pick List

The Pick List serves as a roadmap to the Stores room, guiding users to the shelf locations of the required stock. It also allows users to write notes about the Trace numbers of the stock being picked.

Use of Tablets

If tablets are available in the Stores room, there is no need to print a Pick List. A user can pick up a tablet, access the electronic Pick List in RAAS, and use it to navigate the Stores room, directing them to the shelf locations of the required stock. The user can also record stock takes and Traces directly into the electronic Pick List on the tablet.

Assigning a Pick List

Users can take ownership of a Pick List by assigning it to themselves. Once assigned, the Pick List will no longer appear on the Material Requests Dashboard.

If no user assigns a Pick List, the first user who issues stock to a Part Request in that Pick List will automatically become the user assigned. Once assigned, the Pick List will no longer appear on the Material Requests Dashboard.

How does a Production Engineer cause a Pick List to be created, and how do they ask for stock to be “Picked Now”?

The Production Engineer must add part list line items to the Job Card and create Part Requests by clicking the Process Items button in the Job Card Detail window. The Process Items / Create Part Requests pop-up allows the Production Engineer to forward Part Requests to a Pick List, making the newly created material requests visible on the Material Requests Dashboard.

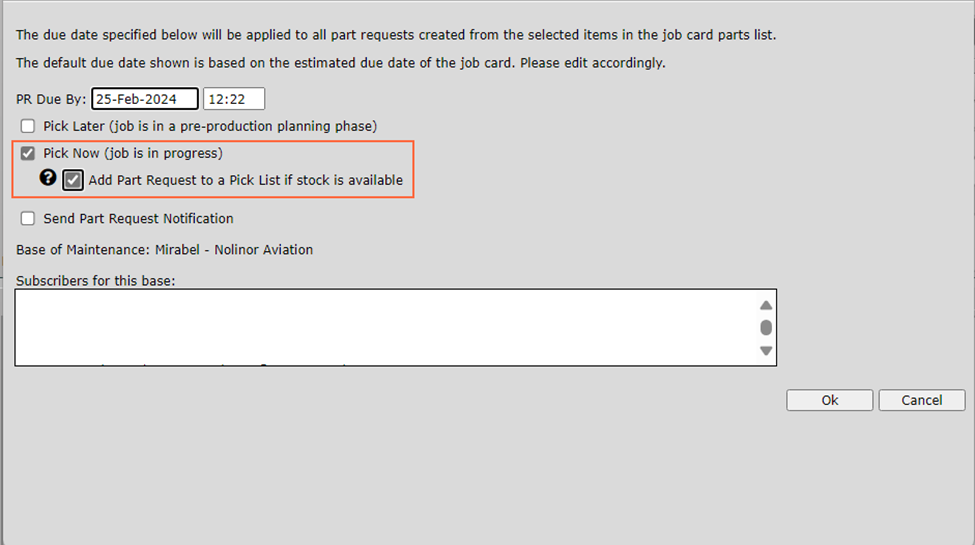

Figure 1: Production - Pick Now

The Pick Now checkbox will be automatically selected if Part Requests are created for a Job Card with an Open status. An Open status indicates that the Job is in progress, meaning materials are needed immediately. Users can toggle this checkbox at any time, regardless of the default setting.

The Pick Later checkbox will be automatically selected if Part Requests are created for a Job Card with a status of New. This status indicates that the job will be completed in the future, and materials are not needed immediately. Users can toggle this checkbox at any time, regardless of the default setting.

The checkbox labelled “Add Part Request to a Pick List if stock is available” forwards created Part Requests to a new Pick List, which will have an Open status. This checkbox also sets the status of the created Part Requests to Open. This automation ensures that newly created Part Requests appear on the Material Requests Dashboard.

Company Setting “Suggest Part Request addition to a Pick List if stock is available and job is in progress” affects this checkbox. If enabled, the “Add Part Request to a Pick List if stock is available” checkbox will be automatically selected when the user selects the Pick Now checkbox. The user can toggle this setting at any time, regardless of the default.

NOTE: Part Requests will only auto-forward to a Pick List if stock is available. If no stock is available, the Part Requests will have a status of New and will appear in the Part Request Listing as usual.